Research and Development

R & D has played a pivotal role in transforming IIL business and will continue to drive future growth.

Four different R&D centres working in different streams

State of the art laboratories with ultra modern equipments

Qualified and experienced scientists

R&D centres have delivered many successful products and are ready with a future pipeline

Investing in R&D today for a better tomorrow will allow IIL to stay ahead of its competition in the long run

R&D - Chopanki

Vision

IIL In-House R&D Centre recognized by DSIR, Ministry of Science and Technology, New Delhi

Development of New Formulations; ecofriendly & ready-mix solutions for farmers

- Development of New Technicals (Active Ingredients)

- Optimizing parameters for process of technicals for cost reduction

- Work on effluent treatment to minimize cost for it

- Replacement of toxic solvent

- To work with DSIR, Ministry of Science and Technology to contribute towards the growth of Indian agriculture

- Contribute towards the growth of Indian agriculture

- Process development for import substitution

- Registration of the products

Salient Features

- Experienced and dedicated scientist in R&D

- R&D is well equipped with all utilities. We have 6 fumehoods where 12 reactions can be carried out simultaneously

- All lab procedures are carried out as per GLP guidelines

- Pre-inspection audit for GLP recognition done

- Well furnished and best- equipped R&D laboratory with all safety measures

- Chopanki was the IIL’s first R&D centre and was established in 2004

- Well-designed instrument and process lab

- International exposure to R&D scientists

- Participation in National and International conference

- Patent granted for import substitute products like Imidacloprid and Acetamiprid, MNIO and PMIDA

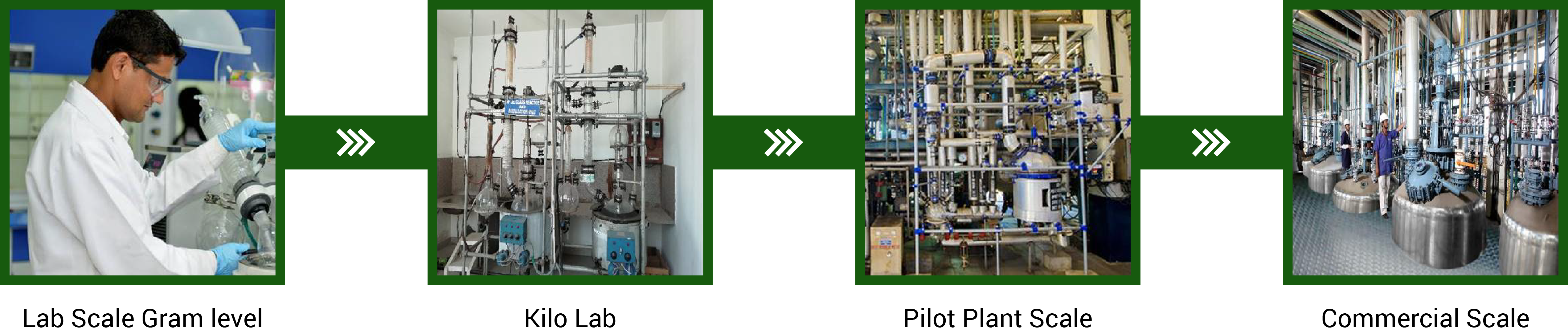

Process of Scaling Up from Lab to Commercial

In House R&D Labs for Testing and Commercializing Potential Products at a Low Cost and Shorter Turnaround Time

R&D - Dahej

Vision

- Process improvement of existing products with respect to cost

- To develop the process for new products /intermediates in terms of competitive cost, energy efficient and environmental friendly to stay ahead of farmer’s requirement and market competition

- Formulation development

- Backward integration

- Contribute for safe and eco friendly practices in agriculture

- Adopt and implement new research technology

- Design and Development

- Project approval to commercialization

- Product registration (CIB/Export)

Salient Features

- Established in 2014

- Well equipped with latest technology and facility

- New molecules development, process scale up and technology transfer to plant

- Impurities synthesis and characterization

- 2 Labs with fume hoods and all required facilities.

- Separate dedicated ADL facility with GC, HPLC etc.

- Plant trouble shooting/support

- Five batch analysis as per GLP guidelines

Unit Process

- Grignard

- Friedel-Craft akn/acn

- Reduction (Using Pd/C, Rany Ni, Sodium borohydride)

- Pressure reaction (Hydrolysis, Hydrogenation)

- Telomerization / Cyclization

- Halogenation (Cl2n, Br2n, Fn)

• Phosgenation (Using Triphosgene)

• Diazotization

• Phosphorus / Sulfur chemistry

R&D - Biologicals

Vision

- To invent new biological solutions for crops.

- To facilitate and commercialise biological products.

- Working to enhance the effectiveness of existing products.

Salient Features

- Equipped with bio assay and production facilities, Viz: Isolation, detection a of biological micro organisms.

- Developed and commercialised VAM (Vasicular Arbuscular Mycorrhiaze)

- Developed and commercialised kayakalp & KK Pro, Soil Energizer.

- Looking forward to development of 3-4 new biological products

Products Commercialised

- MYCORAJA : Vasicular Arbuscular Mycorrhizae based fungal formulation

- PRIME GOLD : A biologically fortified PGR

- MILSTIM : A liquid organic manure

- ROOT BEAD : For increasing root nodule formulation in pulses

- KAYAKALP : A consortia of micro organisms for soil enrichment.

- KK Pro: A consortia of micro organisms for soil enrichment, a product under FCO.

- SURYA ZINC+ : Zinc Solubilising Bacteria capable of fortifying produce with Zinc and will support combating diabetes

- GLOMUS ARBUSCULAR MYCORRHIZAE

R&D - OAT & IIL Chopanki

Vision

- Contribute to sound crop production through novel sophisticated crop protection agents and support the rich diet and health of people

- Creation of new agrochemicals with high safety to mammals, animals and non-target organisms and no impact to environment

- The residue of this product will be insignificant so that the crop can be used for consumption even after one day of spray

OAT & IIL Journey

First time, a Japanese company established such facility in the field of agro-chemicals in India 45+ scientists are conducting research

Approved by DSIR, Ministry of Science and Technology. We have 5 Japanese leading the R&D centre

Lead by renowned scientist with more than 20 year of experiences in the field of agrochemicals

Laboratories

Synthesis

4 Synthesis Laboratories

Analytical

Equipped with latest machines and equipment like NMR and UPLC-MS to analyze and characterize new molecules

Biological

Ultra modern green houses to conduct effective in-house testing Breeding rooms, bio-assay rooms and spray cabinets